Applications of Ultrasonic Sensors & How They Work

Ultrasonic sensors solve sensing challenges across virtually every industry because they work where other sensors can’t. In chemical plants, they measure corrosive liquid levels without contacting the material. On automotive assembly lines, they detect randomly positioned parts despite varying colors and surface finishes. In food processing facilities, they provide sanitary, non-contact measurement. In oil refineries, intrinsically safe models monitor tank levels in explosive atmospheres. This versatility explains why ultrasonic technology has become the go-to solution for thousands of applications worldwide.

The technology’s advantages are straightforward: ultrasonic sensors detect any material that reflects sound—metals, plastics, glass, liquids, cardboard, even foam—regardless of color, transparency, or surface texture. They work reliably in dirty or dusty environments where optical sensors fail. They measure without physical contact, eliminating wear, contamination, and maintenance.

10 Real-World Applications of Ultrasonic Sensors

Migatron’s ultrasonic sensors solve critical sensing challenges across manufacturing, process control, and automation. Our proven technology delivers reliable, non-contact measurement in applications where other sensors fail.

Tank Level Sensors

Non-contact liquid level monitoring for chemical storage, water treatment, food processing, and petroleum tanks. Works with any liquid—corrosive chemicals, viscous materials, or high-temperature fluids—without contamination or probe maintenance.

Tanks Sensor Applications:

- Chemical tank level monitoring

- Water/wastewater treatment

- Oil & gas storage tanks

- Food & beverage ingredient tanks

- Pharmaceutical batching systems

Featured Products:

- RPS-429A-IS (intrinsically safe)

- RPS-409A (Analog Voltage)

- RPS-401A (Analog Current or Voltage)

- RPS-426A (stainless steel housing)

Production Line Sensors

Automated presence detection, counting, and positioning for manufacturing lines. Handles varying product sizes, colors, and materials in dusty, oily environments where optical sensors struggle.

Production Line Sensor Applications:

- Part presence verification before assembly

- Jam detection and prevention

- High-speed parts counting and batching

- Box height detection for sorting

- Stack height control in palletizing

- Gap measurement between products

Featured Products:

- RPS-400 Series (compact 22mm housing, 5-30″ range)

- RPS-150 (wide-beam for misaligned targets)

- RPS-401 (Range & Hysteresis Controls)

Distance Ranging Sensors

Precision distance measurement for position feedback, process control, and quality inspection. Continuous analog output enables real-time control and monitoring.

Distance Sensing Applications:

- Web tension control (paper, film, textile)

- Roll diameter measurement

- Machine tool position feedback

- Profile and contour measurement

- Gap control in manufacturing processes

- Quality control and dimensional inspection

Featured Products:

Intrinsically Safe Sensors

Certified for hazardous locations and explosive atmospheres with flammable gases, vapors, combustible dust or mines with firedamp conditions. ANZEx, ATEX, IECEx, and C-UL-US approved for Zone 0/1/2 and Class I/II/III environments.

Intrinsically Safe Sensing Applications:

- Oil & gas tank level monitoring

- Chemical solvent handling

- Grain elevator level detection

- Mining conveyor monitoring

- Paint booth and coating operations

Featured Products:

- RPS-429A-IS (ATEX/IECEx/C-UL-US certified)

- RPS-409A-IS3 (C-UL-US Class I/II/III)

- RPS-409A-IS2 (ANZEx, ATEX, IECEx, & C-UL-US)

Additional Applications

- Process Control: Loop control, dancer roll monitoring, tension measurement in continuous web processes

- Material Handling: AGV navigation, pallet detection, bin occupancy sensing, warehouse automation

- Robotics: Collision avoidance, pick-and-place verification, process monitoring

- Vehicle Detection: Car wash profiling, automotive assembly positioning, parking management, loading dock safety

- Hopper/Feeder Control: Parts level detection in vibratory feeders, bulk material monitoring

- Roll Diameter: Laminate roll, tissue, paper, textile and non woven roll material handling

→ View more specific applications

How Ultrasonic Sensors Work

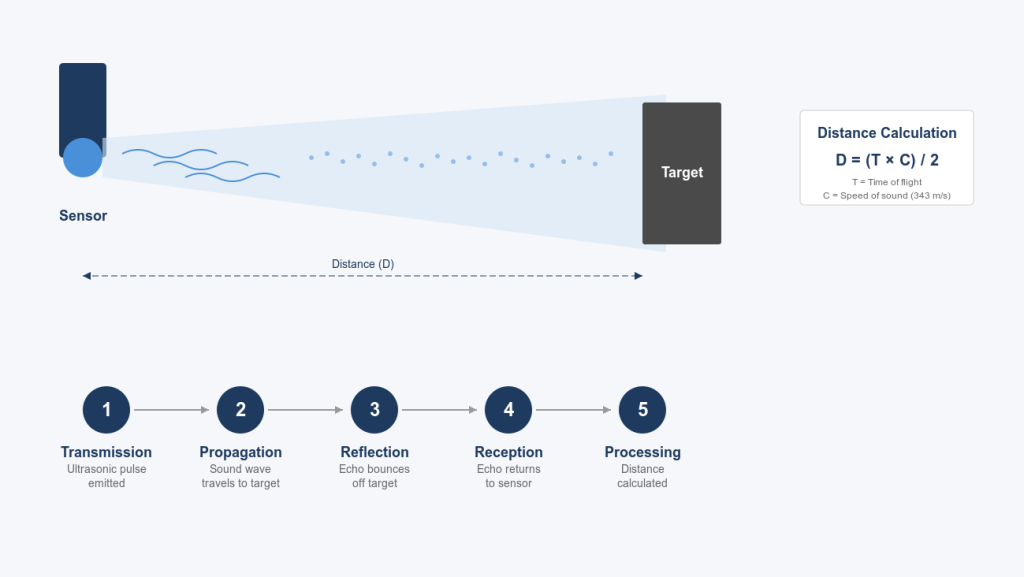

Ultrasonic sensors use high-frequency sound waves (20-200 kHz) to detect objects and measure distances without physical contact. The sensor emits ultrasonic pulses and measures the time for sound to reflect back from a target.

Distance = (Time × Speed of Sound) / 2

5-Step Measurement Process:

- Transmission – Piezoelectric transducer emits ultrasonic pulse

- Propagation – Sound waves travel through air in cone-shaped beam

- Reflection – Waves bounce off target surface

- Reception – Returning echo detected by same transducer

- Processing – Electronics calculate distance, generate output signal

Temperature Compensation

The speed of sound changes with air temperature by about 0.2% per F. Since ultrasonic sensors measure distance based on the speed of sound this change can also effect the sensor readings. However, some sensor models have built in temperature compensation to compensate for the speed of sound changes. Sensor models without temperature compensation are typically used in indoor applications where the temperature remains fairly constant. Sensor models with temperature compensation are typically used outdoors or in other applications that experience broad temperature changes.

No Temperature Compensation: RPS-150, RPS-401, RPS-401A

Temperature Compensation: RPS-409A, RPS-412A, RPS-4000

Why Ultrasonic Technology?

✔️ Universal Material Detection

Detects any material that reflects sound: clear glass, dark plastic, shiny metal, liquids, foam, cardboard—regardless of color, transparency, or surface finish.

✔️ Environmental Immunity

Unaffected by dust, foam, humidity, or ambient light. Continues working reliably in dirty manufacturing environments where photoelectric sensors fail.

✔️ Non-Contact Measurement

No wear, no contamination. Critical for food processing, pharmaceutical, and clean manufacturing. No probes or floats to maintain in tanks.

✔️ Various Sensing Ranges

From 2 inches to 40 feet depending on configuration. This allows our sensors to be used for almost any application in this sensing range.

✔️ Intrinsically Safe Options

Certified for hazardous locations. ANZEx, ATEX, IECEx, C-UL-US, approved sensors for flammable gas and combustible dust environments. MSHA approval pending for Mining in the USA.

Types of Ultrasonic Sensors

Proximity (Switching) Sensors

- Simple ON/OFF detection when objects enter preset range. Ideal for part presence, jam detection, level switching.

- Popular Models: RPS-401 (Range and Hysteresis Controls) • RPS-450 (AC-powered) • RPS-150 (wide-beam, 35° tilt tolerance)

Ranging (Analog) Sensors

- Continuous distance measurement with proportional analog output (0-10 VDC or 4-20 mA). Essential for tank level, position feedback, roll diameter.

- Popular Models: RPS-409A (Analog Voltage with Temperature Compensation) • RPS-429A-IS (Intrinsically Safe) • RPS-401A (analog voltage or current output)

Technical Considerations for Selecting a Sensor

Temperature Compensation

Sound speed changes ~0.2% per °F. Without compensation, temperature swings cause significant measurement errors.

- Standard: Internal temperature sensor for slowly changing ambient conditions found indoors like a factory.

- Advanced: RPS-409A-IS2 with temperature compensation can be used outdoors with broad temperature fluctuations.

Beam Patterns & Target Angles

Ultrasonic energy spreads in a cone, not a laser beam:

Minimum Sensing Distance

All sensors have a minimum sensing distance or “blanking zone” near the transducer where targets cannot be detected. Ensure sensor minimum range is less than your closest target position.

→ Technical resources & documentation

How to Compare Ultrasonic Sensors for Your Application

Selecting the right ultrasonic sensor means balancing factors like range, output type, housing, and hazardous location rating. Migatron’s comparison chart simplifies that process for our most popular sensors, helping you quickly find the best fit for your application.

🔍 Filter Sensors by Your Requirements

| Model | Sensing Range | Output Type | Housing | Temp Comp | Hazardous Rating | Type | Key Applications |

|---|---|---|---|---|---|---|---|

| RPS-401 | 4″ – 80″ (varies by model) | 2 Solid State Relays | PVC | No | — | Object Detection | Short-range tank or distance monitoring |

| RPS-401A | 4″ – 80″ (varies by model) | Analog Voltage (0–10V) or Current (4–20mA) | PVC | No | — | Distance Measurement | Short-range tank or distance monitoring |

| RPS-426 | 4″ – 80″ (varies by model) | 2 Solid State Relays | Stainless Steel | No | — | Object Detection | Food and beverage or washdown zones |

| RPS-426A | 4″ – 80″ (varies by model) | Analog Voltage (0–10V) or Current (4–20mA) | Stainless Steel | No | — | Distance Measurement | Chemical processing and metal finishing |

| RPS-409A | 4″–144″ (varies by model) | Analog Voltage (0–10V) | PVC | Yes | — | Distance Measurement | Tank level, material detection, general automation |

| RPS-409A-2P | 3″ – 144″ (varies by model) | Analog Voltage (0–10V) or Current (4–20mA) varies by model | PVC | Yes | — | Object Detection | OEM automation machinery |

| RPS-429AA-IS | 4″-80″ (varies by model) | Analog Current (4–20mA) | PVC | Yes | Class I, Div 1, Zone 0 | Distance Measurement | Intrinsically safe tank level monitoring |

| RPS-429AV-IS | 4″-80″ (varies by model) | Analog Voltage (1–5V) | PVC | Yes | Class I, Div 1, Zone 0 | Distance Measurement | Intrinsically safe tank level monitoring |

| RPS-409A-IS2 | 4″–216″ (varies by model) | Analog Voltage (0–10V) | PVC | Yes | Class I, Div 1, Zone 0 | Distance Measurement | Intrinsically safe tank level monitoring |

| RPS-409A-IS3 | 4″–216″ (varies by model) | Analog Voltage (0–10V) | PVC | Yes | Class I, Div 1, Zone 0 | Distance Measurement | Intrinsically safe tank level monitoring |

| RPS-412A | 3″–16″ (varies by model) | Analog Voltage (0–10V) or Current (4–20mA) varies by model | Stainless Steel | Yes | — | Distance Measurement | High-precision measurement; lab and process control |

| RPS-4000 | 24″–480″ | Analog Current (4–20mA) | PVC | Yes | — | Distance Measurement | Tank level |

| RPS-400-6P | 2″–6″ | NPN | PBT | No | — | Object Detection | Compact tank or distance measurement |

| RPS-400-30 | 5″–30″ | NPN | POM | No | — | Object Detection | Transparent/clear plastic container detection |

| RPS-150 | 2″–80″ (varies by model) | 2 Solid State Relays | PBT | No | — | Object Detection | Short-range sensing, automation lines |

| RPS-150A | 2″–80″ (varies by model) | Analog Voltage (0–10V) or Current (4–20mA) | PBT | No | — | Distance Measurement | Short-range sensing, automation lines |

| LCU-40APW | 4″–40″ | Analog Voltage (1–10V) or Pulse Width | PVC | No | — | Object Detection | Conveyor object detection, packaging lines |

| RPS-450 | 5″ – 72″ (varies by model) | 2 Solid State Relays | PBT | No | — | Object Detection | High-Speed Conveyor Product Presence & Overflow Detection |

No sensors match your filters

Try adjusting your filter selections or

Comparing Key Sensor Parameters

- Sensing Range: Different applications demand different measurement distances. Migatron’s lineup spans from short range precision models such as the RPS-412A (ideal for fine-tolerance measurement and position control) to long-range options like the RPS-4000, capable of monitoring targets up to 40 feet away. Knowing your target distance and required accuracy helps narrow the field to the right series.

- Output Type: Ultrasonic sensors can deliver analog or on/off feedback depending on the control method.

Analog output sensors—offering 0–10 V or 4–20 mA signals—are ideal for continuous level or distance measurement.

Switching output models provide on/off control for presence detection or simple limit monitoring.

Many Migatron sensors, such as the RPS-150, are available with multiple output configurations to match your PLC or control system.

- Hazardous/Ordinary Locations: Hazardous areas require special consideration. Migatron’s Intrinsically Safe sensors-like the RPS-409A-IS2, RPS-409A-IS3, and RPS-429A-IS-are approved for Class I, Division 1 and Zone 0 environments, ensuring safe operation in explosive atmospheres. For standard industrial settings, ordinary locations, rugged PVC or stainless-steel housings withstand dust, moisture, and temperature extremes commonly found in manufacturing, water treatment, and material-handling applications.

- Housing: Physical size and construction play a role in system integration. The RPS-426’s rugged stainless steel housing provides resistance to harsh environments, making it ideal for industrial applications where harsh chemicals are used. The RPS-401’s compact and versatile PVC housing allows for easy mounting in space constrained locations, such as conveyor systems.

- Accessories: A few core accessories streamline setup and ensure dependable performance. The PD6000 Process Meter provides power to the sensor, local display and relay set points for any 4–20 mA or voltage output sensor. SPC-701/704 Controllers add relay functionality for analog outputs. Migatron also carries a variety of cable lengths and styles for our sensors with quick disconnect feature, standard models include some cable. Contact us for more information on accessories.

Sensor Selection Guide

Use this guide to narrow your search, then contact our engineers for a specific recommendation

1. What’s your sensing range?

- Closest distance: _____ inches (select sensor with lower minimum)

- Farthest distance: _____ inches (select sensor with higher maximum)

2. Detection type?

3. Environmental conditions?

- Hazardous location → Intrinsically safe models

- Wet/washdown → IP65/IP67-rated sensors

- Chemical exposure → PVC housing (RPS-409A)

4. Target alignment?

5. Output requirements?

- On/Off (relay/transistor) → Proximity sensors

- Analog voltage (0-10 VDC) → Ranging sensors, short cable runs

- Current loop (4-20 mA) → Ranging sensors, long cable runs or noisy environments

Need help selecting? Our applications engineers can recommend the optimal sensor for your specific requirements.